When a world famous premier long-established yard like Baltic Yachts makes a serious decision to go ‘street racing’ the result is never going to be anything less than outstanding

The Baltic 68 Café Racer, named for the stripped-down street racing motorbikes of 1960s London’s rockers, is an ambitious vision of the probable future direction of composite sailing yachts.

More than half the hull structure is made of natural flax and it’s decked with FSC-certified cork. The electric powerplant uses hydrogeneration and solar while away from the dock. The air conditioning can be run in eco mode by solar power alone and the bilge pump filters oil and microplastics. Her eco credentials are well established but what of the street racer pedigree?

There are many “holy grails” touted, promised, offered in sailing and ever since non- overlapping headsails became the norm and easy sailing became the fashion, the final frontier was to have a mainsail that delivered performance without the hassle of running backstays.

When you are a shipyard with the reputation of Baltic Yachts you are often tasked with the seemingly impossible and finding the right partners to deliver creates a sense of pressure that, when harnessed, produces exceptional results as an illustrious history demonstrates. Recognising that it was going to take a technical breakthrough in sail design and a complete rethink of mast geometry and then to combine them, was the light bulb moment.

Starting with the Doyle Sails developed structured luff technology it is useful to acquaint or re-acquaint ourselves with what this is and what it means in real terms for the end user. Doyle’s cableless technology has been shifting the industry relentlessly in code sails and has been highlighted in these pages before, but the step into structured luff jibs, whilst entirely logical, is perhaps less understood. This is truly the evolution behind the revolution and has a similar improvement in performance and handling to the cableless technology which preceded it. The technology has many applications, for new builds like the Baltic 68, Infiniti 52 and others now under construction where all the gains can be integrated into the boat and rig design, and also for existing boats that were not designed or built to take high loads, where performance or ease of use can be enhanced.

There are many cases of sail designers being optimistic about the capabilities of the rig design where luff sag is greater than expected . Structured luff sails can offset that even on yachts not designed for the technology from the outset.

Structured luff headsails significantly reduce the required load on the headstay without increasing headstay sag, often reducing this sag and allowing more area in the leading edge of the headsail. The ability to make bigger sail shape changes where the loading on the front of the sail has a big effect of sail flying depth also gives the sails a wider effective performance range and reduces the requirement to have many headsails to cover the wind range. This is particularly pertinent when considering the Café Racer where the primary brief is for easy sailing with high performance. Changing a jib on a 68ft yacht twohanded would really eat into your sailing time and so having a sail that can change gears and thrive in a wider range of conditions is gold dust.

This technology has been proven repeatedly, with yachts such as the MC38, Infiniti 46 and up through 100 footers like Comanche to superyachts where the gains in straighter headstays and load reduction really start to deliver significant weight saving, both in rig weight and boat weight not least by requiring fewer sails to be carried.

The structured luff jibs reduce the runner loads that are required, which allows the option of a no-runner/ easy sailing rig to be seriously and credibly assessed. The increased sailing range and enjoyment with the headsail, coming as part of the package, Doyle now turned their attention to the use of Structured Luff technology in the mainsail. In for a penny…

As the use of high backstay loads reduces, the stiffness requirements in the mast also change and the bending of the mast via the backstay becomes less effective. This is where a similar concept to the Structured Luff headsails is developed to use the membrane itself to do this work rather than the backstays.

Consequentially, this also can reduce the mainsheet load requirements depending on the geometry. With a balance between the sail shape, structure of the sail and the mast design and stiffness, the Baltic 68 Café Racer achieves the mast bend range requirements for the mainsail without needing any backstays.

There are some minor considerations, such as the main cunningham now being a far more integral part of the setup, with more power, but the same proven logic from the structured luff headsails allows the structured luff mainsail to have a truly groundbreaking influence over the mast design.

Marstrom built its reputation on high-performance rigs, originally in Olympic classes, pioneering autoclave production back in the 1980s. With a strong background in multihull rigs the idea of not having backstays is far from unique for Torbjorn Linderson and his team in the spar division at Marstrom. With a strong history of innovation and experience outside of the marine industry, Marstrom was the perfect partner to take this concept to the next level.

The Baltic 68 Café Racer as a concept does not work if the rig package cannot keep up with the vision of the owner. This places a great deal of expectation on the design team led by Javier Jaudenes, who has developed the yacht to a brief that is often touted as easy sailing but often falls far short of this. To make this work, the Café Racer sports a Marstrom rig which is designed to sail with no aft support in flat water conditions in a breeze. No runners to slow the tack or gybe and add stress to the few hours the owner has been able to steal away for a sail. Impressively, in spite of having no runners for most sailing conditions, the tube weight is in the same region as a conventional rig.

Above: after de-moulding, the Café Racer 68’s hull is lowered onto a trolley for finishing. Note the rakish dreadnought bow profile, the trap door for the bow thruster and the anchor that stows flush against the underside of the bow, eliminating the risk of chafed topsides if the boat becomes wind-rode in an anchorage.

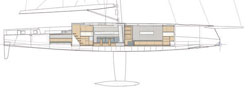

Below: the Café Racer’s interior is deliberately simple with the ends kept mostly empty for optimum weight distribution

Marstrom achieved this rather impressive result by taking what they describe as the “system approach”. This approach perfectly suits the collaborative nature of the design process, a key strength of Baltic Yachts. It is all very well to be ready to buy into the technical gains available from the structured luff sails but if the mast maker cannot then integrate this “new normal” into their mast design programmes then the benefit potential is reduced and the entire concept falls at the first hurdle.

Taking the time to discuss spar properties rather than rig properties where the full equation encompasses tube as well as rigging properties combined with the overall geometry of the tube and the stiffness of the hull structure is essential if an Icarus moment is to be avoided.

The rig concept itself is not new, being pioneered by Bergstrom/Ridder in the 80s where surprisingly skinny alloy rigs without aft rigging powered their pioneering ULDB designs Thursday’s Child/Hunter’s Child and Route 66. Whilst the Café Racer rig is not quite a full Bergstrom/Ridder design it does share similar characteristics, such as the long spreaders and increased spreader sweep aft.

Thanks to a stiff hull structure from the maestros on the shop floor at Baltic Yachts and use of Carbo- Link solid rigging, the rig geometry has been reduced from the typical B&R sweep of 30 degrees to a slightly more moderate 28 degrees. The final evolution of the original rig concept is that the rig no longer retains the reverse diagonals thanks to improved engineering and stiffness of the mast tube itself.

Provision has been made for runners to be used in more extreme conditions, particularly driven by sea state and in possible nose-diving conditions. However, as the yacht goes through her paces this summer, more will be learned about when and where the limits for this ground breaking approach are in reality.

Baltic Yachts prides itself in having an open mind for new concepts; coupled with their can-do approach and almost 50 years of experience in adopting new technology, they feel that the Café Racer changes things in more ways than the immediately obvious. Sometimes taking things away is far more challenging than adding them. Less really can be more.

Click here for more information on Baltic Yachts »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store