For some time now they have been monitoring developments in this growing sector but now South African and Dutch designers Simonis Voogd have entered the performance multihull space... in some style

The performance luxury catamaran market has been growing quickly, with many designers and builders entering this sector. The plethora of new ideas being presented are exciting, driven by smart people using cutting-edge design and engineering tools, advanced composites and good old-fashioned boatbuilding insight and skills. The new KC54 from Kinetic Catamarans represents the latest in this genre, squarely hitting well-thought targets of quality, performance, comfort and style.

Concept history

It was in December 2018 that Bob Hayward and Leon Scheepers had recently bought the Harvey Yachts boatyard in Knysna, South Africa and had a 60-foot carbon catamaran designed by Simonis Voogd well into build. A meeting with Alex Simonis in Cape Town to discuss which project the yard should take on next evolved into a discussion of how to launch what they intended to be a new worldrenowned brand: Kinetic Catamarans.

With a strong cultural heritage in cost-effective boatbuilding in both carbon-infused composites and traditional materials, the challenge lay in what new product size to offer . To go large in size would appeal to a small market, whereas going smaller would have a broader appeal but more price sensitivity and less flexibility in features.

‘We are a semi-custom yard making performance carbon cats,’ says Scheepers, ‘so we are inherently more expensive than the production boats. Fifty-five feet seemed like the right target since it’s the upper limit for a cruising couple to handle comfortably, and keeping the boat under 55ft would help with marina berth spaces in some regions. Going smaller to 50ft might open us up to more buyers, but people are still going to want to load the boat with paddle boards, diving gear, washer dryer, etc. So we decided it was better to keep to the higher end of this range and asked our design team at Simonis Voogd to come up with a proposal in the 53-55ft range.’

But the gap between this and the 60-footer under build was too small so Hayward and Scheepers decided to add two feet to the 60. ‘This would also give us more space on the aft steps for getting on and off the tender, swimming, and fishing,’ says Hayward, who was taking this boat for himself. ‘Also, terminating the outer hull skin short of the stern creates a pad for stepping on and off the boat when it’s side-on at the dock. The 60-footer thus became the KC62.’

The Kinetic team then wondered how to define the DNA of the new boat and its yard and identify who is in its market – will this be a yard producing comfortable performance cruiser cats that you can race or a more racing catamaran with less features, that you can still cruise? This decision would go to the core of the KC brand. Active racing fleets of Gunboats, HHs and similar boats are on the US East Coast, in the Med and Caribbean. The first KC62 would also be out there racing, having also made a commitment to enter the LA-Tahiti Race. But exactly how broad is this market?

‘After a healthy debate we decided we are building performance ocean cruisers that you race,’ says Scheepers. ‘We want to target monohull sailors who are interested in the comfort of catamarans, but want a fast, responsive and fun boat to sail, as well as catamaran sailors who want to trade in for a quicker boat. Our boats will be comfortable but we will keep them light and as easy to sail as possible.’

This adaptability is important: the expectations of racing-only clients can be met with fewer interior elements to save weight while also enjoying a turbocharged sail plan. Conversely, if a client wants to focus on cruising, the boat can still be pre-built for racing with strong spots on the coachroof for sheeting and in-hauling the genoa. This flexibility in turn helps resale value because expectations can be met for generations of future owners.

Design execution

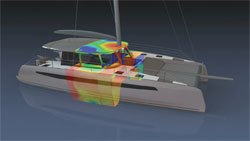

The brief for Simonis Voogd to create a raceable cruising design between 53-55ft came with another sensible request. Catamaran performance is highly sensitive to the loaded weight and fore and aft trim – get this wrong and the boat will miss all its target speeds. So rather than create a design with a target weight defined in light ship trim, they were asked to provide a design with a target weight that people will actually be sailing it in, which turns out to be 18-20 tons.

‘This was important,’ says Maarten Voogd, ‘because we want to keep the leeward hull from sinking too far into the water under load. This also keeps the bridgedeck high to reduce wave slap.’

Next came important decisions on how the features and options offered on the KC54 could fit within the weight targets. The hulls had to provide four comfortable cabins (two with en suite heads) or a three-cabin owner’s version where the spare cabin in the owner’s hull can convert to a fourth cabin when needed.

Popular elements from the KC62 would also be adopted, like the large main salon with open views, and a few other design details such as having a curved traveller mounted on the coachroof rather than a straight traveller on the bridgedeck transom: this allows the traveller to be dropped without tightening the leech of the main. To give versatility on draught and performance, both centreboard and daggerboard versions would also be offered, as would the size of the carbon spar package from Marstrom.

‘Most importantly the boat also had to have clean lines and be a looker,’ says Hayward.

The first set of plans arrived in early 2019, only a few months after the initial meeting. KC62 hull number 01 was completed and launched in May 2019, shipped to the US in July, and being readied for the Annapolis Boat Show in October. Here it was decided not to formally launch the KC54 but to show plans to potential buyers and solicit feedback on details.

The initial plans specified the mast to be mounted above the bulkhead on the foredeck with all control lines leading aft in covered channels around the outside of the salon to the outboard sections of the aft cockpit. Having the mast stepped this way on the bridgedeck would be simpler to build and lighter.

However, in Annapolis the KC62 showed well and people liked its large salon with 360-degree views, its forward interior helm and forward cockpit, and they wanted to see the same features on the KC54.

‘Maarten [Voogd] was with us at the show and said it could be done with some redesign effort,’ says Hayward. ‘We’d need to add a compression post, an athwartship beam and reinforce the coachroof mullions. It would add complexity and some weight, but we’d also be able to increase the salon size, add the forward helm station and move the mast to a more preferable position further aft. Another benefit was that the increased infrastructure would also add rigidity to the boat. So it became time for another one of those central DNA decisions!’

At that time the mould for the KC54 hulls was already started, so the team had to decide quickly on the next move, and by the end of Annapolis show they decided to pull the trigger and make the design change. Within a month new plans arrived which showed the forward cockpit space to be about the same size as the KC62, seating five people.

“Based on our experience with the KC62, this cockpit not only improves the sailing function, it turns out to also become a social centre on the boat and beachfront real estate. We decided to make this along with the coachroof-mounted mast and large open salon key features of all of our boats,’ says Hayward.

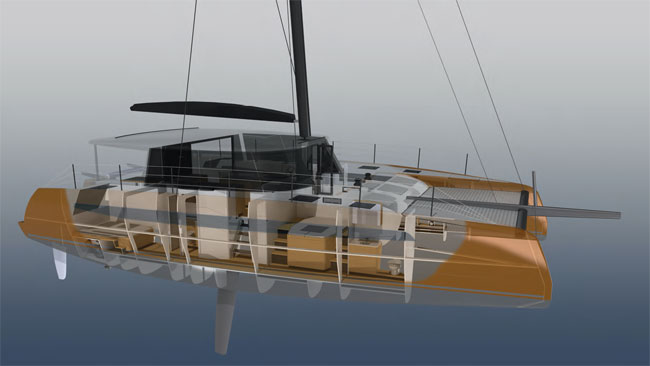

Above: the brief for Simonis Voogd called for a versatile and genuinely raceable cruising design with a target weight that took into account a typical ocean cruising payload while providing an upgrade path for those owners who are keen to maximise the yachtʼs performance potential with an ultra-light interior and a race-spec rig

Key details

To make the boat accessible to a cruising couple, the team at Kinetic had to address other key details in the design phase: (1) the need for easy sail controls to raise and lower the sails; (2) make anchoring easy; (3) make docking easy; and (4) provide solid reliability and aftersales service.

Hayward says the last of these is easy to address: ‘We are fortunate to have good partners in Cay Electronics in Newport who did our systems and electrical equipment specifications, in addition to being able to offer after-sales service. The same holds true for Rigging Projects in the UK for the carbon spar and rigging, and North Sails for the sails. We are also dedicated to only using readilyavailable high-end parts and equipment.’

Anchoring any multihull can be a challenge, but with forward cockpit now in the KC54 design this allowed the team to manage this issue by having the anchor recessed into the forward bridgedeck and having the anchor locker immediately forward of the forward cockpit. This enables the bridle to be attached and detached whilst standing in the cockpit.

‘We had begun testing the Dockmate docking system on the KC62,’ Hayward says, ‘which controls the engines and windless and allows boat to be kept into the wind using a joystick remote whilst standing on the foredeck. It also controls lowering and raising the anchor. The Dockmate system was working well so anchoring was handled. Dockmate also addressed ease of docking as it integrates the drop-down bow thruster with the engines and allows the boat to be controlled from the joystick remote at the dockside rail.’

The remaining issue to tackle was arguably the most relevant for performance-minded sailors who want to have as few barriers as possible to enjoying their time under sail: efficiency and ease of boat handling, particularly for the shorthanded crew. This is handled through several features:

- electric winches with forward sails on electric, continuous and singleline furlers

- self-tacking jib hydraulic mainsheet and Antal line driver for the main traveller

- a roller-furling boom for the fullbatten 25-30% square top mainsail to achieve fast sail reduction while retaining upper mainsail sail area.

The latter system does, however, require some specific conditions for its use… Hayward explains: ‘The boom angle to the mast needs to be 87 degrees for the sail to roll correctly and the issue was how to set the boom reliably. Even when using low stretch line for the topping lift and the mainsheet at preset positions, there is still the possibility to create stretch variances and inconsistent rolls.

‘So, working with Offshore Spars, the first suggestion was to have a system that uses the mandrel length inside the boom, but this would be complicated. On a monohull you can simply put a chock in the vang to set the boom angle, but our boom is only one metre off the coachroof and we didn’t want to lose mainsail area to create space for a vang.

‘We eventually figured it out: our traveller is coachroof-mounted and curved to the arc of the boom and the boom is low to the roof, so this allows for use of a king post which drops down from the boom onto a cup on the mainsheet cart. The length of this post will be adjustable to set the boom at the correct angle, and tightening the mainsheet will put the boom in position for the furl. The cup on the mainsheet cart will pivot to allow for boom swing. Lowering the traveller will also enable the main to be shortened off the wind without having to sail through 90 degrees.’

The topping lift and mainsheet are the backups in the system and the mainsail can be lowered without having to leave the front cockpit. For remote monitoring a camera could be placed under the spreader so that the helmsman could check on progress of the roll. And at anchor the king post does away with the need for a topping lift or boom crutch.

More adaptations in design

Offshore multihull owners vary in how they want to drive: some like the convenience and protection of an in-cabin station, while others want to have a direct feel of the breeze and spray. The KC54 offers both as standard, with a forward interior helm and two aft tiller stations. The second KC62 that’s in build has a more complex three-wheel helm setup with Jefa Steering. The unused stations are disengaged with lowtorque carbon shafts and gearboxes to retain lightness of feel. The helm seats fold away into the outer bulwarks to leave the areas above the aft steps clear when not in use.

‘Naturally buyers wanted to have this feature on the KC54,’ says Hayward, ‘but there wasn’t sufficient space for the aft stations to be organic to the boat and not seem like a subsequent add on.’

Another challenge presented itself from a Dutch buyer’s request to have a bridgedeck transom drop down to become a swim platform bridging the aft steps. The team agreed this would be great feature and asked Simonis Voogd to redesign the back of the boat to incorporate both this and the helms. After a few iterations both objectives were achieved. The helm stations became organic to the boat and the platform simply lowers onto recesses in the aft steps to minimise extra weight. The aft couch is replaced by two seats with swinging backrests to create the isle and the davits hinge back on themselves to be out of the way. This is an example of a win-win offered by carbon, creating the desired features without incurring significant additional weight, hassle and expense.

Order interest is already strong for the new KC54, with hull number one expected to be ready for the 2021 summer season, and more in the queue.

Click here for more information on Kinetic Catamarans »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store