Aston Harald, Swedish builders of the M32 World Match Race Tour cats, is now ready to move into other areas of high-tech marine manufacturing

The architectural and aesthetic beauty of sailing craft while on the water is one of the many inspirations that keeps us passionate about our sport. Even without being a boatbuilder all of us can appreciate the care and craftsmanship that go into the creation of the best high-tech raceboats.

Yet the details of how these boats are produced can be lost in a rattle of machinery and clouds of dust often located on the far side of the world, where concerns about the impact of the creative process of construction may not always be at a level commensurate with the cultural standards of the customer… At the same time many of the clever techniques devised in the process of production can also be too easily hidden to the observer by the excessive clutter spun off when you are talking many hundreds – or even thousands – of man hours of manual labour.

For this reason the craft of composite boatbuilding, even at the highest levels, has developed a reputation as being a difficult, dirty and untidy business. Much better than it used to be… compared with the days when we grew used to seeing an immaculate raceboat emerge from a grimy shed rented on a project-by-project basis; but even more recently many good boats have come together in conditions from which the average race car manufacturer would run a mile. And as for a representative from the aerospace industry…

But times have changed and by embracing both a no-compromise approach to quality while pursuing a philosophy of clean working, the composites team at Aston Harald are at the forefront of efforts by the composite boatbuilding industry to improve its image.

This Swedish initiative started with Aston Harald founder Håkan Svensson’s Berg Propulsion sponsorship of the Puma programme in the 2011-12 Volvo Ocean Race. With a strong background in manufacturing and a passion for grand prix sailing, Svensson was inspired to dive straight into supporting the sport at a high level with the acquisition of the Marström M32 catamaran programme. At the time this one-design class of exciting, fast, yet easy-to-assemble 500kg carbon cats was gaining interest but production had been unable to meet the steadily growing demand.

With the technical support of boatbuilding legend Killian Bushe, builder of no fewer than five consecutive Whitbread/Volvo Ocean Race winners, new carbon tooling for the M32 was manufactured in 2014 with sufficient precision to ensure the absolute integrity of every hull and deck component while delivering a much larger number of boats.

This tooling had to be perfect, so that the pre-preg carbon laminated moulds would not distort even when repeatedly used to cure components in an 11mx2m autoclave at bake temperatures of 120°C. Without both precision and robustness the components created would not achieve the minimum tolerances essential for a true one-design product – something that is more challenging when using the best high-tech, rather than mid or low-tech – materials.

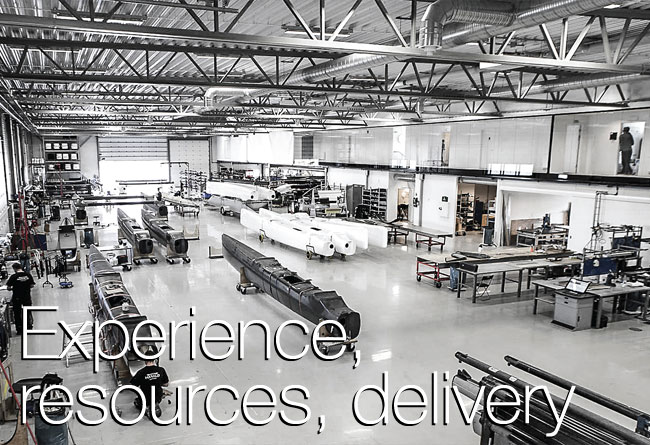

Aston Harald’s 11m autoclave (above) is now used for the construction of the M32 cats on the World Match Racing Tour, but it can equally be used for fabricating virtually any other mid-sized composite components. The Hönö facility is maintained to clean-room standards throughout

Aston Harald achieves this build consistency with a strong dedicated production team, outstanding resources and the benefit of a new 3,700m2 facility on the island of Hönö outside Gothenburg which the company moved into in December 2015. M32 production demand is now met with impressive efficiency: 40 M32s have been built in less than one year, and when at full production two M32s can be built in one week, all the while maintaining the same strict quality standards.

‘Our number 1 priority is quality,’ says Aston Harald vice-president Martin Krite. ‘We spend as much time as necessary to ensure our processes are sound, and do not compromise just to save time. We strongly believe that, ultimately, this represents value built into the final product.’

To create these quality products and expand into new ventures Aston Harald has made a considerable further investment into its facility in Hönö, which is divided into two buildings: a laminating shed of 700m2 run by Batt Battison, a longtime colleague of Bushe through multiple Volvo and AC projects, and an assembly shed of some 3,000m2.

To showcase their build quality to visiting clients and boat sponsors and also to improve on their production efficiency, these facilities are always kept spotlessly clean and tidy to the highest modern standards. This is a core philosophy for Bushe, whose experience building all three race-winning VO70s, ABN Amro and Ericsson, and overseeing the build of Groupama for the previous Volvo Ocean Race, indicated the benefit of maintaining a clean production environment beyond just meeting minimum health and safety standards.

‘We had over 8,000 visitors while building those boats,’ said Bushe. ‘The visitors were our sponsors and guests, so we needed to maintain a presentable work space, and being clean matters. By using clean and neat standards in all phases of our production, assembly and finishing, we actually saved time and with no added cost. And there were obvious benefits to the health and happiness of the work team.’ Krite says that they intend to have the same showcase appearance at Aston Harald. ‘We want to show off our products and that they are being built to the highest standards. We don’t want to have a separate showroom that is isolated from the facility because we would like our visitors to appreciate the care and craftsmanship that go into everything that we build.’

In the boatbuilding trade the word is out on this relatively young entrant to the market. Bushe says they have a large number of new build inquiries – plus a high demand from all over the world for employment at Aston Harald.

Yet the working talent here is not all imported, with most of the team based locally due to a strong local culture in manufacturing and the invaluable assistance of Göran Marström, the original builder of the M32. Bushe says that within six months employees who knew almost nothing about high-tech composite boatbuilding are being trained to be completely proficient in the trade. This human success is largely down to Aston Harald’s investment in the future, developing a training programme that to date has successfully educated some 50 people in various areas of production and assembly.

No boatbuilding operation can be successful without a local culture of supporting contractors, with the facilities and talent base of equivalent quality, and here Aston Harald is in a strong position. ‘Even though physically we’re on an island, we are not by ourselves. All around us is a network of suppliers and contractors that contribute to our production success,’ says Krite. ‘There is a long engineering history here with a strong work ethic that makes it relatively easy for suppliers to achieve our standards in quality and production.’

This solid base of labour and suppliers, the ability to be adaptable and even expandable with their new facilities and a proven track record in producing high-quality products for the high-performance market makes Aston Harald well positioned to become a significant new force in all levels of high-tech composite construction.

For anyone seeking to build the next generation of composite rocketships, of up to 70ft or even beyond, whether high-speed multihulls built for stadium sailing or an offshore monohull to chase new oceanic records, a visit to Hönö to explore what this new player in the field of composite technology has to offer should prove well worthwhile.

Click here for more information on Aston Harald »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store