North Sails’ director of design and engineering JB Braun explains an innovative engineering solution that brings top-down furling to Load Sharing Sails

‘Continually pushing the leading edge forward, North Sails has collaborated with Future Fibres to engineer the next refinement to Helix sails – a cord that allows all the performance benefits of Load Sharing Technology and the reliability that comes from top-down furling for sails with mid-girths greater than 60 per cent. This load sharing system is exclusive to North Helix sails,’ says Braun.

‘The latest advancement in Load Sharing Technology is the Helix Luff Cord, co-engineered by North Sails and Future Fibres. This exciting new product was designed and manufactured by North Sails’ partner Future Fibres, who took their vast experience and technical expertise in torsion cable and furler integration to the next level on this shared R&D project. Designed to work exclusively with North Helix sails, the innovative product brings top-down furling back to self-supporting code sails. The cords are built to the precise tensile stiffness which allows for optimal load sharing between the cable and the sail. As the sail trim changes, the cord to sail load ratio remains the same. The onboard benefit is a safe and reliable top-down furl, while reaping the benefits of a free-flying, forward-projecting Helix sail.

‘Along with Future Fibres’ project engineer Seth Cooley, we employed several tools within the North Design Suite to first validate the concept and then to understand the aeroelastic coupling when a Helix sail is exposed to a fluid flow. Membrain, our exclusive load analysis software, helped the team understand the loads on the boat, mast and sails, right down to the specific load sharing ratios between cord and sail. The designs were then run through Flow, which analysed wind pressures across the sail as cord and sail load up together,’ Braun explains.

‘As the Helix concept has grown exponentially over the past year and a half, it became clear that bottomup furling of 75 per cent mid-girth sails was unreliable at best,’ says North Sails president Ken Read. ‘It would have been easy to simply retrofit standard torsion cables back into Helix. But that isn’t our style. We needed to develop a system that incorporated light weight and ease of handling along with clear sail shape and performance advantages. A tall task. Fortunately JB and Seth and our teams came up with a product that is truly a breakthrough.’

‘The Helix Luff Cord allows for top-down furling at a fraction of the size, weight and stiffness of past luff cables. This in turn enables load sharing and allows the flying shape of the Helix sail structure to fly unencumbered by the stiffness, weight and diameter of a conventional cable,’ explains Braun.

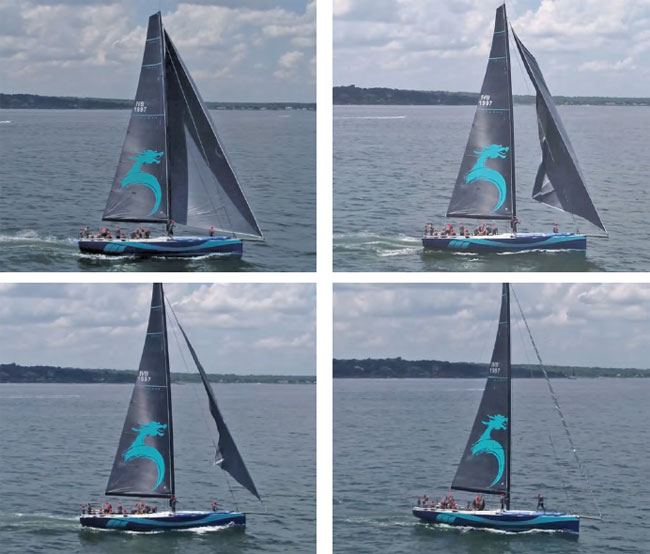

Above: this sequence shows how the Helix Luff Cord delivers a safe, reliable tight furl all the way from head to foot, ruling out the risk of the sail unfurling prematurely. The TP52 Beau Geste was one of three programmes that tested the Helix Luff Cord and provided valuable feedback during the development.

‘This is the next step in the evolution of Load Sharing Technology. The Helix Luff Cord and sail work together, as opposed to a heavy anti-torsion cable, which is designed to hold the rig up. And the same sail/cord load ratio is maintained through changes in sail trim. This allows the sails to change shape through tack line adjustment while maintaining the optimum amount of luff tension.

‘Since its introduction, Helix has become the choice for cruisers, racers, and grand prix racers because it offers superior flying shapes with less overall loading. Code sails, laminate A-sails, reaching headsails, and staysails have all benefited from our exclusive Helix designs, and the Helix Luff Cord adds easier and more dependable sail-handling to the many other benefits of Load Sharing Technology.

‘Anyone can furl, unfurl, hoist and drop our Helix Code Zero now, at any apparent wind angle,’ adds Sam Richmond, sales manager for North Sails UK. ‘We have been developing and testing luff cords on many highperformance boats including Jethou throughout the past five months, mainly on our Helix Code Zeros.

‘The Helix Luff Cord allows us to reap the benefits of the Helix design with its forward-flying luff and radical reduction in loads on the bowsprit and mast, all while adding the safety and reliability of top-down furling. We no longer have to worry about losing boat lengths during a furl or unfurl, or the danger of handling big sails with bottom-up furling.’

‘The Helix Luff Cord is exclusive to North Sails, part of our mission to make sailing better for all types of sailors,’ Braun concludes.

Bottom-up furling engages the bottom of the sail and is less efficient with the sail’s upper section. Larger and wider-girth sails (greater than 55-60 per cent midgirth) benefit from top-down furling. Bottom-up furling can work on 75 per cent mid-girth Code Zeros with small luff lengths, provided the crew pay attention to the furl.

When a sail furls in the bottom and does not carry enough furling revolutions with one or two turns, the top of the sail is susceptible to unfurling prematurely. If this happens and then the bottom of the sail is unfurled, you get a twist in the luff where the top furls one way and the bottom the other. This is costly during active racing and results in loss of boatspeed, and thus boat lengths.

Helix Luff Cords are developed specifically to work with North Helix 75-65 per cent girth sails. The cord is designed to set with two per cent sag and a load share between 20 per cent and 50 per cent of the total tack load. There are two styles of the Helix Luff Cord - Blue Water and Grand Prix. The primary difference between these cords is their intended application.

Blue Water Cord: to be used as an all-purpose cord, designed for inshore and offshore use where the sails loading could be higher, and potentially used in higher wind speeds or offshore conditions. For the Blue Water Cords a load sharing of 50 per cent is used as the cord’s EA design point; the cord still intended to sail with an 80/20 sail/cord load ratio.

Grand Prix Cord: with a design point load share of 20 per cent, it is intended to be used as a day race cord sail with the crew having tight control on sail loading. It’s generally only applicable on North 3Di Downwind Helix sails.

Click here for more information on North Sails »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store