The comparison between America's Cup sailing and Formula 1 Grand Prix racing is a popular one; but is it valid – especially in terms of technology? Andrew MacFarlan is a graduate of Southampton University's world-famous school of yacht design who now happens to be the Head of Composite Design at Red Bull Technology, 2010 F1 World Champions in both the driver and constructor categories. In a new series MacFarlan and his team give us unprecedented access to what really goes on behind closed doors...

So what is special about Formula 1 design...

Formula 1 car design and engineering is often described as the 'pinnacle of engineering'. While that's arguable, what definitely does separate F1 from most, if not all, other peacetime engineering disciplines is the pace of development necessary to win and to continue winning. Often the gradient and period of positive development that an F1 team can sustain during a racing season, relative to its immediate competitors, can prove decisive in the championship standings. With modern day Computational Fluid Dynamics (CFD) and other simulation tools and wind tunnels that are now available to most Formula 1 teams the rate of development is limited primarily by the ability to (rapidly) turn concepts into reality.

Ignoring financial considerations (which many may be surprised to learn is far from the case in reality), the limiting factors are how quick you can design and make the parts for an event or, conversely, how late can the simulation, CFD and wind tunnel optimisation work continue before being forced to commit to a solution.

What I hope to outline in these articles is the process we, the composite design group at Red Bull Technology, take in turning 3D CAD surface models into fully fledged 'Grand Prix-ready' cars and car parts over the winter in the case of the 'new car' or over weeks, days and hours for all the various development parts.

Driven by aerodynamics

The design of a Formula 1 car is a combination of many factors but a successful package combines excellent aerodynamics, engine power, mechanical grip, flexible weight distribution, driveability and to some extent serviceability. The final car must also be capable of demonstrating these qualities on 19 circuits around the world in a variety of temperature and weather conditions.

The aerodynamic performance should constantly evolve...

To read on simply join us TODAY!!!!!

Please take advantage of our latest subscription offer or order a single copy of the February 2011 issue of Seahorse International Sailing

Online at:

www.seahorse.co.uk/shop/index.php

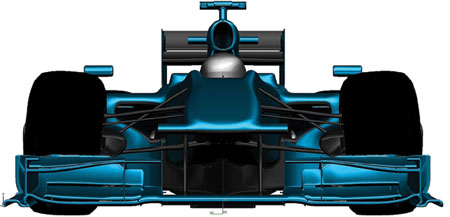

Below: Sign of things to come: a full surface model of Red Bull Racing's RB5 (2009) Formula 1 challenger, runner-up in both the constructors and drivers championships of that year...