... for the finest applications. Meet Zircon, ceramic opening the door to the next level in precision sail trimming

By introducing ceramic bearing technology into its latest line of Zircon blocks, Harken has significantly improved the accuracy with which sail trimmers will immediately match sail shape to changes in conditions.

An undeniable leader in the field of premium deck gear for the past 50 years, Harken is renowned for being at the front of running rigging technology, both in its design and production. The company ethos and the demands of the world class sailors with which it collaborates, requires its technical team to constantly improve its products for racing and cruising alike, and line handling gear has always been one of its specialties.

In the early 1970s, Peter Harken forever changed the way sailors trimmed and eased sails when he dropped a handful of white highdensity composite bearings called Delrin by duPont to the floor. They bounced like crazy. To Peter it was obvious they changed direction very quickly—exactly what was needed to improve the heavy, slow-to-respond blocks that depended on plain bearings or the dead steel balls then universally used. Those Harken white ball bearing blocks began a quest Harken’s still on. How much inertia can be overcome while safely delivering ever-increasing working load capability?

Delrin was a miracle. It remains so in the right applications. But it has its limitations too. Apply too much load and it will begin to deform, making the balls run less freely—a fact alleviated significantly by adding Torlon which is far more crush-proof and impact-resistant where needed.

Years of development have proven one thing: there is no ideal single solution for block bearings. Indeed, sometimes the most effective solution employs layers of balls. Sometimes it combines composite rollers and stainless balls. At the highest end of the performance demand, the balls are eliminated, the rollers become titanium living inside bespoke Delrin cages. The sheaves are titanium too.

But as mentioned, Harken never shrinks from the challenges of competitors or sailors. Its engineers saw incredible performance leaps being delivered in cycling and other high efficiency bearing applications in about 2015 and begin to translate the same material for sailing. A new range of insert-moulded ceramic bearings, aptly named Zircon is its latest offering. Named after the element metal Zirconium which is more commonly referred to as ceramic, from which the balls are made, Zircon blocks drastically reduce rolling resistance, and greatly improve power transfer to the crew for rapid and precise trimming.

At the core of its new Zircon blocks is a single row of ceramic balls which run on ceramic inner and outer races moulded inside glass/nylon sheaves. These ceramic balls are so much harder than even stainless bearings, that without the surrounding like material races, they would certainly wear through and destroy the block from inside out. Ceramic is also much smoother on its surface than any other bearings. The result? Less energy and response time absorbed before they start to move. Quick bearings make for responsive trimming.

An early example of Harken’s use of ceramics was its innovative 2800 Grand Prix catamaran mainsheet system, which was developed in the run up to the Rio Olympics and had become the standard by the 2020 games. The high-efficiency blocks making up these systems feature insert-molded ceramic bearings that significantly reduce rolling resistance and greatly improve power transfer to the crew for simple and very precise trimming. They have now been adopted by virtually all the best foiling multihull sailors-- particularly favored by mixed teams where the smaller sailor trims the main. Zircon sheaves are so freerunning, teams feel free to rig more purchase, without the risk of not being able to ease when the pressure abates. Indeed in even the lightest air, trimmers report it feels like they can actually push the line out of the blocks. Delivered as a 12:1 mainsheet system, it can easily be reconfigured to 10:1 or 11:1 to align with wind strength or crew preference.

Above and below: the new ceramic bearings in the Zircon range of blocks were initially developed for Olympic foiling multihulls.

Harken’s small boat project manager, Matt Schmidt says: ’We optimised the Grand Prix cat mainsheet system for weight and efficiency using ceramic bearings that we now use in the Zircon. This greatly reduces rolling resistance in these high-purchase systems. This efficient power transfer to the crew makes it much easier for them to make the adjustments needed to win when racing these powerful cats at the top level.’

Applied within their designed load capacity, Zircon bearings don’t compress or develop flat spots. The ceramic balls are actually rounder and much less porous on the surface, allowing them to move instantaneously and much more freely. The cages keep the balls the ideal distance apart so they don’t bunch up and stop each other. The result is the most efficient small boat block Harken has developed to date. A very free-running block that continues to spin for a surprising length of time unloaded and thrives within its load range.

Zircon blocks are primarily designed for "hand-generated” loads and are appropriate for use in sheets and control lines or the section of a cascade rig where it meets the trimmer. For comparable bearing sizes, ceramic bearings can take higher compression loads than their plastic equivalent, but there is a smaller safety margin at the top end of their safe working load, beyond which they can crack or crush.

They are not intended to match the “all performance” of, for instance, Harken’s Carbo Block series, which are designed for a broader range of applications.

Schmidt continues: ‘At this point, we haven’t been using ceramic bearings in any larger or higher load applications. We do use ceramic coatings to provide extremely hard-wearing surfaces in winch drums and hydraulic cylinder rods for instance. However, it’s a case-by-case basis, where ceramics can provide improvements.’

The downside of cutting-edge technology is very often increased costs. The material cost of an eightball, caged ceramic bearing dwarfs the cost of the two rows of 25 Delrin bearing balls used in a conventional 57mm Harken Carbo Block. There are even price points beyond what Harken has selected as the bearings become microscopically even rounder, but at some point, the cost no longer justifies the very slight increase in efficiency.

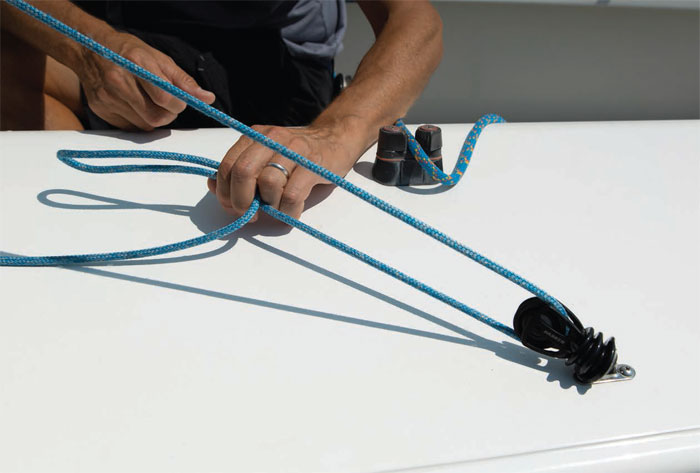

Above and below: Produced in small sizes, Zircon blocks are designed for ‘hand generated’ load applications;

When asked how the ceramic balls wear compared with Delrin or Torlon, Schmidt said: ‘Contamination is the main source of any wear. As with all open bearing blocks, salt and dirt that isn’t flushed out regularly can be a problem. Just by the nature of the Zircon design (a single row of precision fit balls/ races) these are a very tight and smooth-running bearing. Small amounts of wear are more easily noticed as compared to a block with wide rollers or two rows of balls.

‘Ceramics are very hard though, so dirt or salt won’t as easily embed as they would in plastic or even softer metal. Keeping things clean and flushed with water and soap is important. I’ve personally had test blocks on my E scow for three seasons and they haven’t required any cleaning beyond just rinsing in fresh water.’

With regard to lubrication, Schmidt reckons they’re better off without, or at worst the addition of just one small drop of Harken’s One Drop very occasionally. ‘The intent is for the balls to continue to roll and not end up skidding or sliding.’ he explained. ‘Also, over-lubrication can lead to contaminants sticking to the bearings.’

Peter Harken originally designed his ball bearing blocks to make it easier to ease sails in the lightest breeze. He says of Zircon, ‘They really make a huge difference. They feel like you can push on the rope and boom, they react. Or you can load up on purchases and not worry about friction holding them back.’

At full production Harken will offer Zircon blocks in eight model variants, in 40 and 57mm sizes with soft attach versions.

Click here for more information on Harken »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store