America’s Cup and Maxis… now Persico enters the Superyacht field

With a well-established reputation for innovation in building highperformance racing yachts Persico Marine is poised to enter a new chapter with the build of the fourth member of the steadily growing Wally Cento series. Created in partnership with Mark Mills and Pininfarina design, this new 30m beauty, when launched in 2017, will be the absolute latest in combining style, innovation, advanced technology and design. This exciting project will add to Persico’s impressive record of producing the highest-quality composite raceyachts for the top teams in the America’s Cup, TP52 and Maxi 72 classes, Volvo Ocean Race, Imoca 60 and other grand prix fleets.

When looking for the best in reliability and durability in advanced composites, the managers of the Volvo 65 one-design class approached Persico for their hulls. These boats have now raced around the world without a serious failure, with one spectacular exception: when Vestas grounded on a reef it was Persico that took on the major rebuild to put this boat back in the race in one-design trim. This impressive feat convinced Volvo race organisers to contract Persico to build any additional boats needed for the next edition of their gruelling event.

So it was not surprising that after evaluating bids from other teams, and with performance the key criteria, the owner and project manager of Wally Cento No4 selected Persico for their project.

A 22-month design and build programme makes full use of Persico’s latest equipment for the creation of the best possible composite fabrications, including a 2.6 x 7.2m autoclave, four modular ovens up to 45m long, three five-axis CNC milling machines up to 25m, a 9m vacuum table, a 4m-wide plotter, a finish press, a clean room, in-house ultrasound testing, a digital dimensional scanner for reverse engineering plus tooling for roll-forming aluminium and Nomex core material. Efficiently combining this latest equipment means precision tooling alignment, accurate fibre placement and quality control, and with Persico’s advanced processes the exactness of the finished hull shape along with complete weight control.

Since the Wally Cento rule allows small variances in design parameters, and with high performance expected over the range of course types inherent to Wally racing – windward-leewards in addition to coastal races – designer Mark Mills had the design freedom to explore a fresh approach that builds on the success of his work in the Maxi 72 class, a class that is also familiar to Persico having recently built Rán V and Momo. Mills’s concept was for a raceboat that meets stringent Wally standards of design and comfort, rather than a Wally yacht that happens to be fast.

To achieve this high performance, the same central weight concentration was pursued as is typical of the best stripped-out raceyachts. Of course, in a Wally this weight concentration is less easy to achieve, given the large number of mandatory interior elements and many complex systems… propulsion, hydraulics, electrical, plumbing and climate control. The sail control and rigging systems are also below deck, and thus have to compete for space with these other systems. Minimising the weight of these elements and controlling their position without compromising efficiency, as well as the implications for interior aesthetics, required an enormous collaborative effort among not only Mills and the team at Persico, but with project manager Carlo Torre, the many system engineers and the Pininfarina studio responsible for the yacht’s interior.

The Pininfarina team has created an interior in harmony with the onboard systems. The saloon is the most iconic space with the ‘stairs’ the central feature. The steps are like waves, continuing towards the walls and giving life to functional spaces, resulting in an environment mirroring the dynamics of the sea. A combination of clear-coat carbon and light wood will create a contrast to reflect the combination of sportiness with elegance. Fast and sporty lines, with light and dual-performing structures characterise all the spaces on and inside this new superyacht.

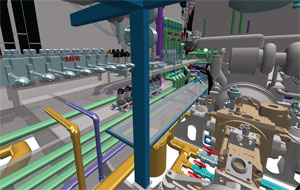

Besides executing a striking interior design in the lightest possible manner, Persico’s expertise in complex onboard systems is reinforced with a recently expanded in-house team that uses state-ofthe- art CAD software to precisely map out installation options within the spaces available. This new capability has been essential in working efficiently with the interior design team at Pininfarina, proof that the investment made in this talent and the latest powerful software tools helps to reposition Persico to deliver not only on performance, but sophisticated luxury as well.

‘This is the real success story in this project,’ says Marcello Persico. ‘We had some experience with this in the successful co-operation in the Volvo 65 project, but the level of co-operation between everyone and the free flow of ideas to improve the complex superyacht systems on a Wally were outstanding.

‘It was particularly good to have had a few months before starting this project when our team could work with Wally, Mills, Pure Engineering and many of the suppliers to work out the key details; we are particularly proud of the high degree of systems integration on this boat.

‘We now have in our technical office people with many years of experience at Wally, and who know well how to build a Wally. But they are now working alongside experts from the America’s Cup who bring their own knowledge of how to build a super-light boat by hunting down structural and detail optimisations wherever possible. I believe the combination of these two skills will lead to something very special.’

Above: the extraordinary detail in which the management systems on Persico’s first superyacht can now be addressed using the latest simulation tools that the company is able to draw upon in-house.

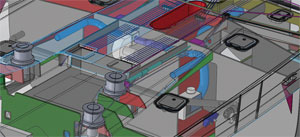

Below: How some ‘large’ deck loadings are resolved; a similar portion of the new Wally Cento is modelled as a render (top) and then as a transparent structural model (bottom). The new yacht features even more ruthless dedication to weight concentration than its successful predecessor Magic Carpet3

The process started with the initial design and engineering of the structures, with help from Giovanni Belgrano and Martin Bivoit of Pure Engineering (see May 2016 Seahorse). Their detailed analysis using FEA tools provided the composites experts at Persico with a roadmap to develop the tooling needed to make these structures and also gave systems engineers like Persico’s Matteo Bisio a chance to start work early on finding efficient layouts.

Next was to position the engine room and power plant further forward than is usual in order to concentrate weight in the centre of the boat; other advantages are the closer proximity of the power plant to on-deck systems such as the cockpit winch package, which is also placed forward just a few metres aft of the mast. This minimises the weight of cabling, tubing and power loss.

The Cariboni line-handling systems are integrated into the main structures and connected so as to be efficient while minimising connection lengths and unnecessary complexity. Volvo Ocean Race and Wally Class veteran Michael Joubert at Southern Spars also brought a great deal of input to the layout and design of these systems.

With Persico being fully equipped with sophisticated CAD-driven CNC milling machines, developing the complex tooling needed to create not only the structures in high-tech composites but also the interior elements in composites and veneers were not a problem.

To make the best job of the flat interior panels, for example, Persico creates composite panels with Nomex cores in a press, exactly the same manufacturing process that the company uses for the super-light RIBs of America’s Cup wing sails.

Because of the high degree of process integration, the complexity of these elements could be seamlessly dealt with through design, engineering, fabrication and ultimately installation. This process efficiency results in maximum strength-to-weight structures, which all contributes, kg by kg, to better performance. In this respect, the fabricated elements of this project embody the Wally philosophy of innovation: by using the right tools, new ideas can be explored rather than just over-engineering old ideas and concepts.

The hull, deck and bulkheads are now complete, with assembly and fit-out starting shortly.

Working with a long timeline that would be the envy of raceboat managers, this project allows the various teams at Persico to use their skills to the full, creating not just another successful performance boat project but a complex and beautiful Wally yacht. This places Persico in an elite field of builders ready to take on the next generation of projects at the sharp end of the superyacht fleet.

FASTER WALLY

– Mark Mills

To produce the most refined high-performance solution to the Wally Cento rule, we assembled a design partnership comprising R&D specialist Dimitri Nicolopoulos from KND/Sailing Performance in Valencia, who also provides design management; Giovanni Belgrano of Pure Engineering, ensuring that the engineering requirements remain at the front of the process; plus Gautier Sergeant, lead designer with North Sails; and ourselves.

Performance progress has been made in a number of areas, one of the first targeted for improvement being to optimise weight concentration far beyond what is typical of a sailing superyacht. Key to this has been the involvement of Carlo Torre of MYT in Monaco and the Persico team with their raceboat expertise, who remained both creative and flexible throughout the extensive development phase.

Hull and appendage development was undertaken with KND/ Sailing Performance, who employ extensive CFD technology in both panel code and RANS, that built on their experience with our 2014 Maxi 72 World Champion Alegre, foiling Imoca 60s, and in developing the Volvo 65 VPP. Targeting the design to a carefully defined weather and course model reflecting Wally events in the Mediterranean, the final hull shape exhibits a combination of low drag in lighter conditions and increased stability in more wind that makes her more versatile than previous generations. The choice of a single rudder further reflects optimisation to a condition set that includes a mix of windward-leeward and coastal courses.

Click here for more information on Persico Marine »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store