CFD has come a very long way since those days of pretty pictures used to illuminate design articles...

Everyone uses computational fluid dynamics (CFD) in yacht design these days but you get what you pay for. Working with the best CFD experts in the industry can deliver a real competitive advantage – or a big commercial benefit.

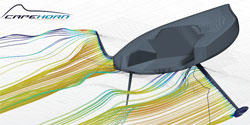

One of the factors that contributed to the remarkable boatspeed advantage of Alex Thomson’s Hugo Boss over the rest of the Imoca fleet was an extensive programme of CFD simulations. What’s less well known is that Alex brought in a specialist CFD team, Dr Rodrigo Azcueta’s Cape Horn Engineering, to help deliver that advantage. Even now, with the next-generation Hugo Boss in build, the detail of that work remains shrouded in secrecy.

‘We were fortunate to be able to count on Rodrigo's expertise in foil design and CFD analysis,’ Thomson says. ‘For CFD analysis, Rodrigo and the team at Cape Horn Engineering are always our first point of call.’

Cape Horn’s founder, Dr Azcueta, is one of the leading CFD experts in the industry. With 30 years’ experience at the cutting edge, he has worked with America’s Cup and Imoca 60 teams and three consecutive Volvo Race winners, while also consulting for a wide variety of design offices, from race-focused naval architects like Ker, Reichel-Pugh and Judel/Vrolijk to superyacht specialists such as Hoek, Dykstra, McKeon, Frers and Briand.

Besides new build projects, Cape Horn also helps to fix design faults in existing yachts – correcting the design of a superyacht rudder, for example, to give precisely the right balance and “feel” on the helm – and they are often called in to help design new appendages, rigs and sail plans for maxi racers to prolong their competitive lifespans or to re-optimise them after a change in rating rules.

The Sailing Yacht Research Foundation’s Wide and Light Project is another example of Cape Horn Engineering’s work. ‘This project examined the accuracy of simulation codes and engaged five different CFD specialists who carried out blind analyses on an identical test matrix using their preferred computational codes,’ Dr Azcueta says. ‘We used the flow solver STAR-CCM+, and delivered the closest data to the tank.’

Mass-market boatbuilders also call in Cape Horn for designs. When Bénéteau set out to reinvent its First cruiser-racers, Roberto Biscontini was commissioned to design the new flagship First 53 – and Cape Horn was brought in to refine the design, ensuring the volume distribution was fully optimised. ‘From the very start of the design process I was keen to involve Rodrigo Azcueta,’ Biscontini says. ‘I’ve known Rodrigo for many years and consider him a true expert in the field of CFD and hydrodynamics.’

Many naval architects and racing teams are building up their own in-house CFD capabilities but when performance is crucial, it pays to outsource. If you’re serious about winning or keen to avoid expensive mistakes, you need the best CFD team in the business. ‘Building up in-house CFD can be very costly in the longer term,’ Dr Azcueta says. ‘CFD experts available for hiring are rare, so design offices may have to resort to juniors. A lack of experience will lead to poor-quality results, delayed delivery and therefore increased costs. People, computers and software licenses might not get used 100 per cent of the time, adding unnecessary overhead. Software vendors will present potential clients with an optimistic view of what is achievable, which may lead to disappointment. A dedicated CFD company will have larger resources allowing them to deliver results in a shorter time frame, at a reduced cost and of highest quality.’

Meanwhile, leading sailmakers use Cape Horn’s expertise to develop new product lines. Dr Azcueta’s unique AeroSim portal is an ondemand service that gives sail designers direct access to the most advanced and powerful CFD technology available, whenever they need it.

‘We love racing yachts, always have, always will,’ Dr Azcueta says. ‘And we love the sea. We are now accepting more projects from the wider marine industry, where our CFD can make a real difference for the environment. I personally feel very strongly about this. As a company we have grown in a competitive field where tiny percentages can make the difference between winning or losing. This can translate into big numbers when it comes to reducing emissions, saving fuel, improving performance, for instance by developing wind-assisted propulsion.’

Click here for more information on Cape Horn Engineering »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store