It is no great surprise that when fast-growing Australian performance clothing innovators Zhik turned their attention to the creation of a new high-performing offshore seaboot the result would be a little different…

It wasn’t the best of legs for Team AkzoNobel. Leg 3 of the Volvo Ocean Race was a 6,500-mile sleigh ride through the Southern Ocean from Cape Town to Melbourne. Things went wrong for the Dutch crew when they mistimed a gybe in strong winds and big rolling seas. Laying the boat on its side out of the gybe led to damage to the mainsail battens and the mast track and forced the crew to make running repairs while trying to maintain as much speed as they could.

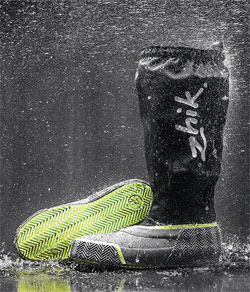

It’s at times like these that you want everything working in your favour, which is why Team AkzoNobel – as well as Dongfeng Race Team, who finished second on this leg – opted for Zhik as their technical apparel partner. Recently voted Best in Class by Yachting Monthly magazine in the UK and Dutch sailing magazine Waterkampioen, Zhik’s ZK Seaboots don’t look like anything else on the market. In fact, Zhik’s design team started with a blank slate to come up with something that looks and performs quite differently in several key respects.

Uppers

After reviewing the evolving requirements of the modern offshore sailor, Zhik set about developing a new boot type, using a combination of sealed neoprene and soft rubber construction, with glued and blind-stitched seams plus additional seam tape reinforcement to provide 100 per cent waterproof protection from the elements. Drue Kerr, Zhik production manager and senior designer, was lead designer on the ZK SeaBoots project. ‘Based on our research and conversations with experienced offshore sailors, our seaboots value dryness over breathability.

‘Breathable boots tend to suffer from a well-known issue… they leak easily and trap water between the membranes. In fact, they can they stay wet and heavy for an “unpleasantly” long time. This then limits the thermal insulation they can provide when wet. So we went down the route of achieving dryness above all else.’

Neoprene was chosen over leather for its non-absorbence and insulation qualities. The neoprene is used in combination with rubber for foot protection, support and durability. Seams are glued, blindstitched and seam-taped to ensure they are waterproof. A strong rubber outer wraps over the lower boot and foot for protection and foot support, and the sealed neoprene uppers extend up the leg like a snug-fitting, warm sock, designed to fit closely over base layers and leggings.

The boots have additional waterproof gaiters which are worn over the trousers to reduce water douses up the leg from waves; these in turn integrate with Zhik’s Isotak ocean and offshore trousers and Aroshell coastal trousers.

The gaiters are secured with a draw cord and, in anticipation of any water draining down inside the gaiters, a perforated neoprene gusset in the lower section ensures the gaiters are rapidly self-draining, preventing any water collection. Silicone grips on the front of the boot uppers hold the gaiters and trousers in place.

Additional detailing in the construction includes hi-viz strips to help crew identification at night as well as handy reinforced handles to aid speedy kitting up, a welcome feature at the moment of that AkzoNobel crash gybe in the Southern Ocean…

Soles

Zhik’s patented non-marking sole is used extensively in the company’s footwear for its ultimate grip on a range of wet deck surfaces from non-slip grip to high-gloss varnish. This soft, bendy, rubber sole has a dense zigzag grip which is designed to dispel water to the outside as soon as the foot makes contact with the deck. This avoids the aquaplaning effect and allows for the super-grippy rubber to take full effect on the surface.

Above: to many sailors the immediate distinguishing feature of the new Zhik boot is the move away from a breathable core fabric to a system which prioritises keeping the water out. A breathable fabric is very effective in minimising the build-up of sweat, but conversely once it is wet it can stay that way for a long time. A poll of experienced offshore racers encouraged this switch of emphasis towards keeping the sea out in the first place; with the sweat build-up being dealt with differently, using the company’s latest and now well proven wicking systems

The sole grip is extended up over the toes and wraps around the heel to provide additional non-slip grip. For offshore crews this is essential to prevent sliding around on deck when working on your knees during a sail change or running across a coachroof or cockpit.

Bart Milczarczyk, Zhik’s global head of design, explained the development process that went into developing the seaboot sole. ‘The rubber compound was engineered by Zhik R&D staff. We tested this in a lab and then in the real world onboard, a process that took over 18 months.

‘The lab testing consisted of cutting up lots of shoes to create specimens. We tested footwear from our competitors in the marine industry and outdoor market. The rubber was analysed by lab technicians to understand the connection between rubber formula, grip pattern and rubber hardness. From this we began to build a picture of which variables worked best. Once one aspect was defined we repeated the same tests with different variables, with the aim of creating the ideal balance of grip, hardness and durability.

‘In terms of grip pattern the Dunlop Volley tennis shoes – which are popular with roof tilers in Australia – proved to have a great pattern. We then produced various tools to define the best combination of rubber and grip pattern. We also carried out extensive abrasion testing. This accumulated knowledge brought us to the final design seen in the ZKs. It’s the highest-grip sole in the wet, which doesn’t mark the deck and also offers excellent durability for daily wear. (As an industry innovator Zhik has to take particular care to protect its intellectual property and the ZK sole is now patent protected.)

‘Once we had the lab testing knowledge we were able to create various items for on-the-water in-use testing. This on-the-water development process went on for a further eight months before we were happy with the final product.’

The midsole

For those (many) sailors who suffer from cold feet or poor circulation inside the boot there is an 8mm neoprene midsole concealed under a supportive EVA inner sole, for enduring comfort and insulation on cold decks. This inner sole also features a moulded heel and arch support to keep the foot securely in place as you move around onboard. The combination of soft, bendy ZK sole and neoprene uppers ensure total flexibility and maximum agility around the deck.

During production every ZK Seaboot is tested twice at different stages of the assembly to ensure that it is 100 per cent waterproof. Pre-rubber application uppers are tested in a submersion tank and filled with air at pressure for a fixed period of time. This checks the integrity of all seams and how waterproof they are. Each production batch of rubber is also checked and tested for its UV resistance, durability and performance. This ensures the quality across production runs and that developments are applied with consistency. After vulcanisation and final assembly all the boots are then tested again in the submersion tank and checked for air bubbles or leaks. To ensure consistency this process is monitored by Zhik’s own QC and production team. Drue Kerr: ‘Product design and innovation are key to our brand and this innovation doesn’t stop at the final design, it flows through the manufacturing process. Our multiple-stage QC process reflects this, ensuring the integrity of the product and demonstrating our appreciation for design.’

Inners

ZK Seaboots are fully lined with Hydromerino, Zhik’s proprietary weave consisting of a quick-drying merino/polyester blended fabric, which provides additional warmth, moisture management and natural odour control. The lining material was developed as a result of tests with Zhik’s base layer ranges, made from merino and their own Superthermal Hydrobase (base layer). Like the Superthermal Hydrobase, the material activates with moisture to wick water away from the skin while the merino element adds warmth and natural antibacterial qualities to the lining.

After such an exhaustive development process Drue Kerr is relieved the Seaboot has been so well received by top sailors. ‘This product unearthed countless design challenges so it is incredibly satisfying to see such a successful result at the end of the process.’

Lisa Blair – ice queen

Last year Australian adventurer Lisa Blair set out to become the first woman to circumnavigate Antarctica – solo, non-stop and unassisted. However, when the rig came down on her Open 50 after 71 days at sea, she was forced to pull out of the record attempt.

Despite, or perhaps because of this setback, she really appreciated her Zhik clothing in such extreme conditions. Lisa was one of the first to trial the ZK Seaboot 800. ‘Zhik’s grippy lightweight ZK Seaboot 800 can be worn the entire trip, it is lightweight and easy to manoeuvre around in. The boots might feel tight at first but they will stretch; so my advice is to fit them so they are comfy and they’ll expand for a sock.

‘I didn’t take any other shoes and I didn’t have to worry about odours; even if I sweated in the neoprene they didn’t smell. The gaiter works really well too, even when I was chest high in water none ever got inside the boots!’

Click here for more information on Zhik »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store