UBI Maior Italia have been doing that exquisite engineering thing again…

first trials of the Jiber equipped J/121

Jiber and Jiber TX

Once the preserve of cruisers and oceanic racers, the headsail furler is now a common sight on yachts of every size and type and increasingly for sails of every size and type. From the Mini 6.50s to the Class40s, from the Imoca 60s of the Vendée Globe to the latest 30m super maxi with their somewhat larger all-pro crews, furler use has also expanded from being deployed merely on headsails and staysails to use with asymmetric spinnakers, Code 0s and the like.

Regardless of which sail is being furled, all furling devices have a tough job to do. In exchange for the convenience of not going to the foredeck to douse the sail, these mechanisms must be able to perform perfectly while under loads from the halyard, the sheet and the wind itself. They need to be durable enough to operate reliably in all conditions without breakage, corrosion, chafe or excessive friction so that crews can be assured that their safety – and race result – will not be compromised by a malfunction.

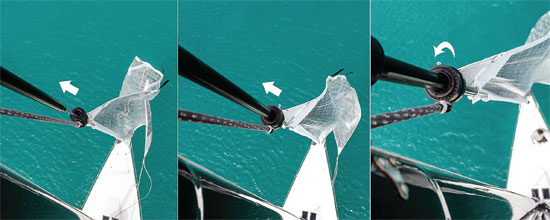

Above: the Jiber in action here with a zip-luff headsail – though the majority of Jiber customers presently use hanked-on sails. The ‘loose’ collar (left) is pulled up the rod headstay with the head of the sail attached; then once the collar meets the alloy upper guide (centre) section it locks onto the section which in turn is connected to the top swivel, thus relieving the rod headstay from exposure to the torsional loads when the sail is furled (right).

This is particularly true for structural furlers, whose strength and integrity quite literally keep the spar aloft, or any furler type where a shorthanded crew may not be in position to troubleshoot problems in harsh weather and rough seas.

The design and fabrication of the system must therefore be very carefully engineered to deliver reliable operation and performance within the limits of their specified use and the varying degrees of ‘horsepower’ that is on tap to operate them. Given these stringent parameters, it’s therefore safe to say that furlers are a critical component to not only the performance, but also the safety of any offshore yacht equipped with them and its crew.

While furlers have been in development for decades, there are now a handful of systems available that combine clever functional design and reliability with the ability to retrofit on an existing stay to save weight, operate efficiently as a furler in a wide range of conditions and allow for the sail to be removed completely in the unlikely event that the situation – and conditions – should ever warrant it. Two of the best-known, and best-proven, of these systems are the Jiber and Jiber TX from UBI Maior Italia.

‘We could see that increasing numbers of solo racers on Class40s, Imoca 60s and the large trimarans were using structural furlers with an anti-torsion cable as the forestay,’ said Vieri Abolaffio, engineering manager at UBI.

‘The approach was good, but it posed limitations for the more typical cruiser-racer owner, so we wanted to improve the concept to broaden the appeal to a larger group of sailors. Specifically we wanted to give them the possibility to adjust halyard tension and to drop the sail altogether when desired.’

Abolaffio and his team kept the principle of using an existing headstay (ie no unnecessary fitting of a separate extruded aluminium headfoil) for its lower profile, lighter weight and easier sail attachment than a luff tape, but they also wanted to make it more friendly. ‘We wanted to develop a system that was easy to operate in all conditions and was also failsafe for these users,’ he added.

What UBI Maior Italia came up with is a structural jib or solent furler that works without the usual aluminium extruded foil. With the Jiber system a rod forestay is linked directly to the drum and swivel, rotating to transmit the torque and furl the sail, while the Jiber TX does the same for composite anti-torsion cables.

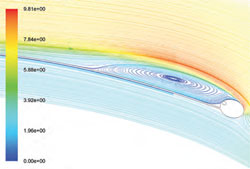

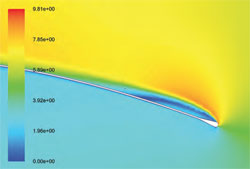

Above: a like for like comparison in turbulence shown using velocity magnitude as calculated with Ansys CFD. The turbulence using a conventional twin-groove headfoil is dramatically greater than with a sleeve luff on a Jiber furler (below).

‘With our system, if something goes wrong you open the halyard lock and the sail comes down fast,’ Abolaffio says. ‘And at the same time the halyard still functions normally and can be adjusted to control luff tension in the sail in the usual way.’

This ability to ‘lose’ a sail quickly makes the system handy for today’s high-aspect staysails, their narrow operating range making a quick deploy/remove facility very attractive.

‘We started studying the system five years ago with rod because it is cheaper, but also more durable, with less maintenance [than composite stays],’ Abolaffio continues. ‘The secret of this system is in the design: the cold heading of the rod ball is shaped in such a way that it allows the torque transfer without dangerous stress concentrations. This was developed using finite element analysis followed by rigorous and extensive full-scale testing.’

In the Jiber and Jiber TX systems the majority of UBI’s customers use soft hanks for sail attachments, a method that is fast coming back into fashion on the newest maxi yachts as well, or a zip bag for when even the smallest aerodynamic gains are relevant to the application. The system is also designed to be versatile, with multiple styles available in the bottom drum:

(1) The Classic drum, whose advantage is that it is less expensive, can attach to standard toggles, has an internal turnbuckle, and there is less clutter on deck. Its disadvantage is that the rotation takes a little more force due to having less leverage.

(2) The Flat furler/continuous line: this is a lower-profile design, so more foot area can be accommodated because the tack point is lower to the deck, the disk is larger so there is better leverage, and the turnbuckle is external so it’s easier to adjust headstay length and tension. This design also features a ratchet to prevent accidental unfurling.

(3) Underdeck: this design has the lowest profile and lowest tack point to maximise sail area, but it is the heaviest of all options and the most complex to instal due to the underdeck space and attachment needed, as well as a suitable pathway constructed for the furler line to be accessible to the cockpit.

Continuous line furling (above) with external headstay adjustment and (below) an underdeck installation

Besides clever design, reliability and quality in component production are also central to the UBI operation, enabling the company to offer a full five-year warranty with all their products. Many components are machined from solid metal by the company and virtually every component is manufactured in-house to avoid the risk of a supply fault. Materials used include hard-anodised 6082T6 aluminium alloy, 17-4PH stainless steel, nickel-coated aluminium-bronze and top-of-the-line rollers and bearings. Composite cables in the Jiber TX systems can be PBO, Kevlar or carbon and the units fit cables from all the major cable producers.

The Jiber has already been installed in numerous custom boats and was recently also selected for use on the new J/121 from J/Boats – which is attracting major interest on both sides of the Atlantic.

J/Boats project manager Jeff Johnstone says: ‘I read about the Jiber in Seahorse and it has turned out to be a perfect fit on our new 121, since this is a boat intended for short-handed sailing. It is equipped as standard on the headstay, but is available as an option for a furling staysail and the masthead Code 0 that tacks to the end of the sprit. We were particularly attracted by the low-profile drum, the ease of use and the relatively modest price for such a high-quality product.’

Barry Hayes of UK Sails in Hong Kong said he chose the Jiber for his own boat since it has fixed some major issues they had. ‘When adding an extra forestay on the bow, you add too much weight with a normal furler, there is a lot of windage, and you can’t drop the headsail without it going in the water singlehanded.

‘So the Jiber was the only option. It’s light, thin, low windage, has single-line furling and it’s set up with the headsail hanked on. So you can drop it on your own even if it’s on the end of the bow. Once the sail is hanked on, the foil controlling the sail is easy.’

Giulio Desiderato of North Sails Italy said, ‘I love the Jiber; it’s a bomb. It allows cruising with the same performance as the racing set-up!’

Testimonies from industry professionals are valuable, but it’s the owners themselves who need to be impressed. Stefano Pozzi, owner of the sleek and innovative new Solaris 50 Paola 3, says: ‘I am very lucky, I can go out sailing every day and the Jiber gives my boat fabulous performance and fantastic handling… even when I am sailing on my own to relax!’

Click here for more information on UBI Maior Italia »

We invite you to read on and find out for yourself why Seahorse is the most highly-rated source in the world for anyone who is serious about their racing.

To read on simply SIGN up NOW

Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse.

Online at:

www.seahorse.co.uk/shop and use the code TECH20

Or for iPad simply download the Seahorse App at the iTunes store